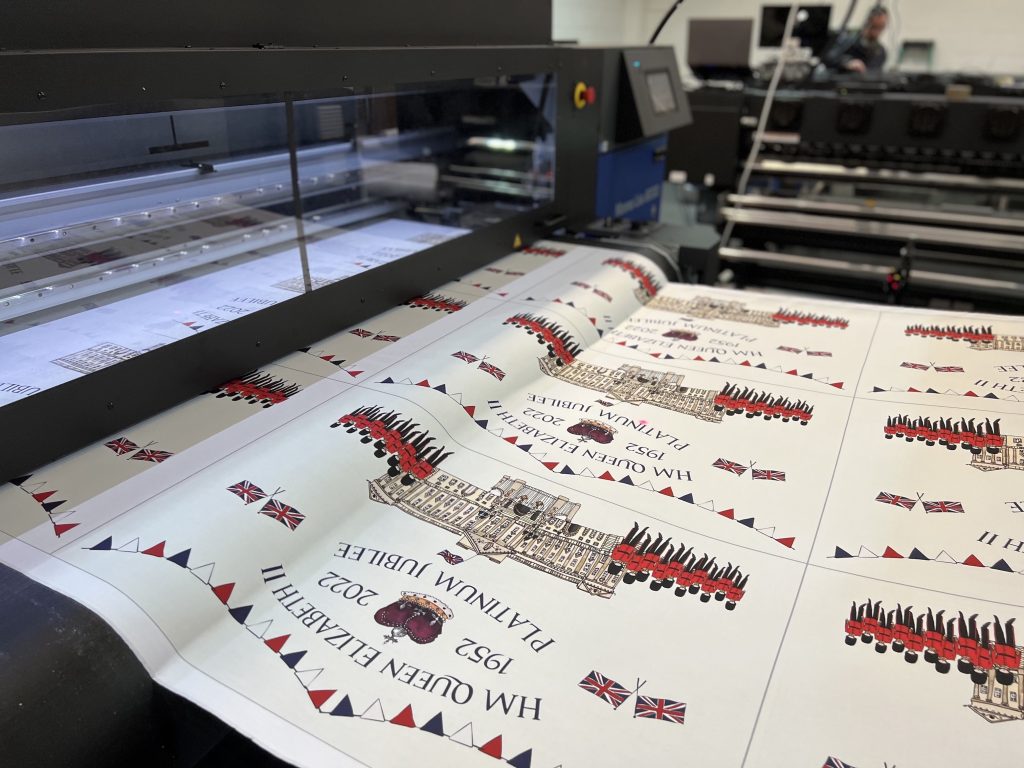

Choosing water-based inks and organic cotton for your brand can help you to breath more easily when it comes to the environmental responsibility of your brand.

In a nutshell using water-based inks means we are reducing the amount of harmful chemicals used in screen printing all of our products. We use less when cleaning the screens after a print run, the manufacture of the ink uses less when making the inks and when we do use chemicals, they are gentle and safe. The inks are simply cleaner, less energy consuming and, in our opinion, better than the plasticised alternatives.

However, making one good choice and going with a water-based ink printer like us, does needs backing up by others to make a difference. The next obvious one to make is asking for organic cotton for your base garment or bag. When choosing certified organic cotton merchandise, you are making a choice that reduces the number of harmful substances used in the growth of the cotton. The GOT’s (Global Organic Textile’s Standard) also means farmers and producers are treated and paid fairly. Looking at the certification of producers like Continental’s EarthPositive® or Stanly Stella really highlight the difference you are making by using their products for us to print onto.

Our water-based screen printing and DTG inks are GOTS approved for use on organic cotton

But using water-based inks and organic cotton doesn’t have to be seen solely as an environmental choice for your promotional item or brand. We have been using the inks since the 1980’s because of the benefits they bring for printing. They are thinner or more viscus than plasticised inks, meaning you can print through finer meshes that allows higher detail in the print. Also wet on wet printing is possible, that allows colours to blend together on the fabric, a well set up 4 colour process print with additional spot and process colours can produce a huge array of colours. These techniques are essential when screen printing fine art for museums and the only way to do it is with a water-based ink.

When making choices for sustainability we also need to think about the longevity and wearability of the products we are making. Water-based inks come up trumps with wearability, they are soft and bright making large prints comfortable to ware especially on finer knit cottons. Washability is also excellent, again when the print is on a higher quality and fine surfaces. Continental Clothing’s, EarthPositive® range of apparel is a great example of a higher quality fine surface to print onto and they discharge print beautifully.

So why do so many printers use plasticised inks? With so many benefits from using water-based inks, it’s a sensible question to ask and our experience it’s down to ease, cost and efficiency. Especially for printers in hot climates, water-based inks can cause a lot of problems due to ink drying into the mesh or changing its consistency in long print runs. The ability to leave the print at the end of a shift and start again on the next, without having to touch the job is another reason printers prefer plasticised inks. It’s also possible to cure the garments at lower temperatures through smaller dryers, again making them more efficient to run. But is convenance a good reason for a UK based printer? We don’t think so.

For you and your textiles, water-based inks and organic cotton can provide your brand with an ethical and higher quality product range. One you can stand behind with confidence!