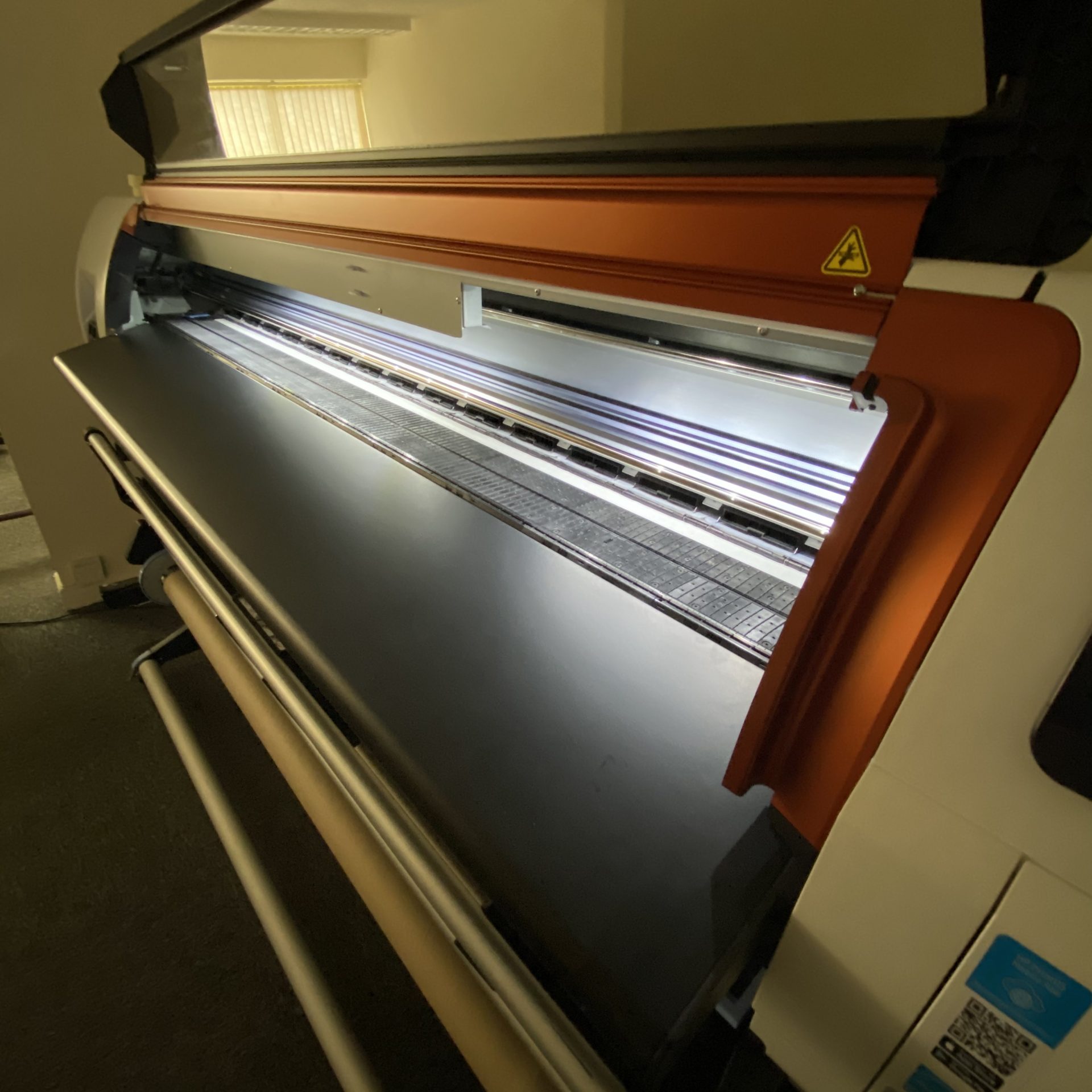

Our Dye Sublimation Printing Process

When it comes to textile manufacturing, we are one of the UK’s leading dye sublimation printing experts, and this method is sure to bring your product ranges to life!

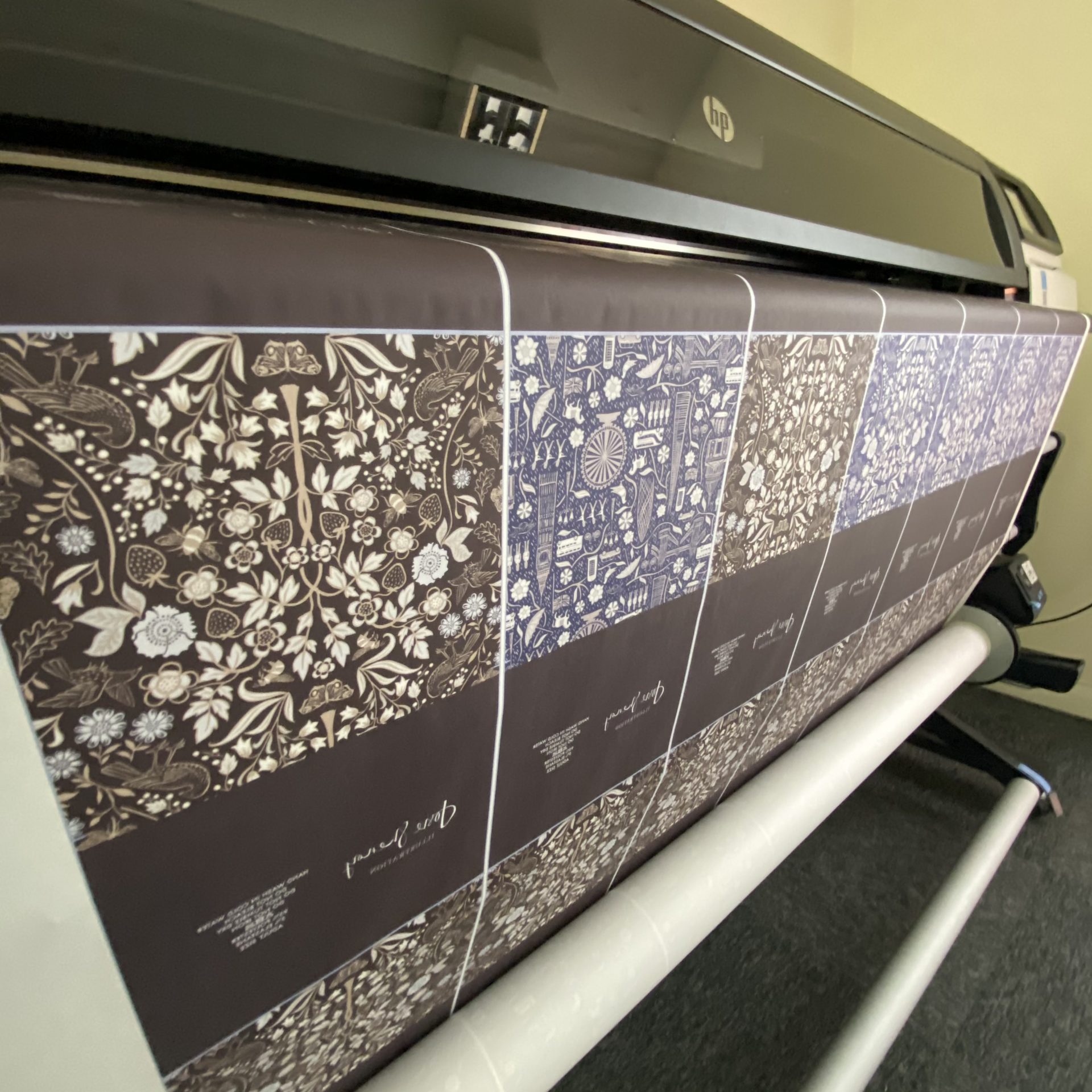

The dye-sublimation printing process involves a computer rip, which is used to process the artwork or design in question before it is printed onto sublimation paper. Once the design is on the paper, it passes through a heat press along with polyester fabric, and this process transfers the design from the paper to the fabric.

Here at Paul Bristow Associates, during our textile manufacturing processes, we tend to use the dye-sublimation printing process for ‘all-over’ t-shirt designs on a poly-elastane fabric, printed leggings and printed face masks. But recent projects have led to us producing bandanas, snoods, sweatshirts and hoodies.

Dye-sublimation printing has many advantages like other digital printing methods, a high level of detail can be achieved, low set-up cost, unlimited colours. Dye-sublimation also has its disadvantages such as the speed of printing when compared to other methods of printing such as screen printing. But when combining the excellent wash results of dye-sublimation printing and recycled polyester that we use for our UK made, all-over printed products, the results are truly unique and exceptional.

This process has allowed us to produce 1000’s of all-over printed t-shirts for companies such as the National Gallery and Tate. These t-shirts’ unique selling point is the fact that a design can be printed all over the garment including sleeves with no limitation. As a leading textile manufacturing company, of course, we make the garments in-house too! The end result is then a product that is 100% made and printed here in the UK!

The minimum order quantity (MOQ) with dye-sublimation printing is 50 products per design and per colour. Although you can break the 50 products down into different sizes.

When you contact us with an image, our fully trained account managers will use their industry knowledge and experience to advise you which print method to use. Access exceptional print quality, with vibrant and high-resolution images, by coming to Paul Bristow for your dye sublimation printing.